Japanese agriculture, forestry, fisheries and food

Highlighted Japanese IngredientMilk and dairy products Made in Japan

- 日本語

- English

Delivered to Your Table Every Day Through Strict Quality Control

Since milk is consumed on a daily basis, we aim for safety and deliciousness through strict quality control. Japanese milk and dairy products can be consumed without any safety concerns. That’s because dairy farmers and processing plants are integrated; cattle farms raise and milk cows, while milk and dairy product processing plants collect the milk and produce products for consumption. The first dairy farms in Japan started on a full scale around 130 years ago. While their history is short compared to those in Europe and the US, Japanese milk and dairy products quickly became must-haves as the Japanese lifestyle became globalized. Japan has 86 million cows and produced 7.65 million tons of raw milk in FY2021. The primary characteristics of Japan-made milk are that it is always of high quality and safe to consume, and offers innovative, delicious, and new tastes. We hope you will try Japan-made milk.

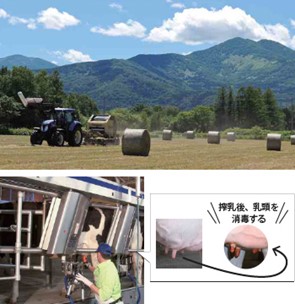

The taste and safety of milk are achieved by providing a comfortable breeding environment and thorough, appropriate breeding management. In addition, careful attention is given to daily hygiene management, especially the prevention of mastitis. Aside from testing each milking cow for mastitis, raw milk is double-checked before being loaded into tanker trucks from bulk cooler storage facilities. Only after an inspection to confirm that the milk meets quality standards, it is delivered to processing facilities.

Quality Refined with Freshness and Safety as the First Priority

Freshness and safety are the most important requirements for milk. Milk and dairy products made in Japan have built a reputation for freshness and safety that satisfies Japanese consumers, who are said to be the most demanding consumers in the world. Milk delivered to milk processing facilities is checked for appearance, luster and color, flavor, fat content, solid non-fat ratio, and bacteria counts. The facilities also perform antibiotic tests. Milk that passes the inspection is sterilized and processed for commercialization without exposure to air until packaged as a finished product.

Many milk processing facilities ensure quality through food safety manuals and work procedures based on international standards such as HACCP, ISO 9001, and ISO 22000 to meet the safety and security needs of consumers.

Japan Milk Creating Good, New Tastes

In Japan, milk and dairy products with novel tastes and textures that go beyond conventional wisdom are being developed. In particular, due to advances in freezing and refrigeration technology, many milk-based desserts and ice creams have been created to meet the needs of consumers. In addition, many yogurt products are being developed as health products featuring excellent taste and high functionality to meet the needs of health-conscious consumers. We are constantly challenging ourselves to make Japanese milk and dairy products more enjoyable for consumers around the world. Please look forward to the future of Japanese milk and dairy products as products that can be enjoyed by all generations and that go well with all kinds of foods.

Universal Japan Milk and Dairy Products Mark

Since milk is consumed on a daily basis, we aim for safety and deliciousness through strict quality control. This mark signifies proof of Japanese milk and dairy products produced by the integrated efforts of dairy farmers and milk processing plants.